Gear Formula Information

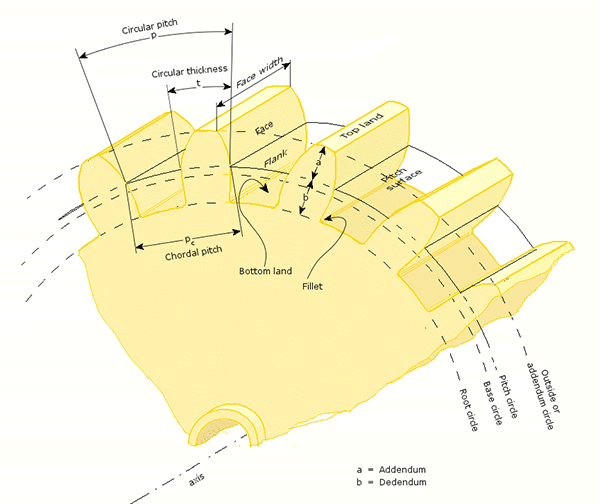

Credit for this image to Mechanicdrive.com

Gears are an exceedingly popular item used in many machines, to transfer motion to other gears on shafts, or linear movement on racks. Many gear-repair & machine shops manufacture these gears, on fast accurate modern CNC gear cutting machines. When you need to have new gears for a particular job! You may have some of the information to hand, or not all the details?

Here is a website that I have used on various occasions to check out gears, to confirm the unknown information or parameters.

You too will find it useful to look things up, now this is not the only one, but one of many! As there are other particularly good websites that will help you out when you most need them. Don’t forget to give them credit for their splendid work, whoever you use to solve your problems.

Gear size and Ratios

Gear size and Ratios can be a big problem in many instants, especially when things go wrong and companies have no backup spares, or no CAD drawings are available to make a new part!

This kind of problem is not as prevalent now, as it was some years ago. With the use of variable speed drives and direct-coupled motors, it can be easy to fit another motor-gearbox unit and tweak the drive setting to achieve the desired speed required.

When Gear Formula Information is Useful

However: this is not always an option where you have multiple output shafts from a special gearbox. In heavy-duty machinery, you will have to find the correct gear to replace the one that is damaged. This becomes an easy job to calculate if only a portion of the original gear wheel with teeth are available?

Should more than half the gear teeth be missing you will need to know, or have a lot more information available to make a replacement gear…? On older machines that are running trouble-free for many years, not all original drawings may be readily available.

Precision CAD drawings may not always be available to manufacture the new replacement gear. Luckily most modern gear cutting workshops have a range of highly accurate measuring equipment, which allow them to accurately calculate the original size of gear and tooth form in use.

If you are left with no options, then the only alternative open to you is to gather all the dimensions by measuring the gearbox shafts centres and other mating gear sizes. You may need to take an impression of one of the mating gears to be able to give your findings to your gear cutting workshop. This method is particularly useful if it is a comparable size gear you need to replace!

So, they can produce new gears for you! Also from this information, you can make a CAD drawing of the gear, which is then available for the future if ever required.

New maintenance people and engineering managers arrive, and companies get taken over, storage space can be moved to new premises and much information in one form, or another gets lost! Older loose-leaf drawings not collated or documented very well may disappear or get mislaid in the system.

With more modern CAD drawings this is now less of a problem, as you can have a new original drawing file printed. Or sent directly to the gear cutting workshop computer system. In these instants, a new gear can be manufactured in a truly brief time. Unless your gear is made from a special composite type material, or you need to have some heat treatment carried out.

The Gear Formula & when to use it

If you are working on a large special gearbox this may be your only route of action. Otherwise, a total gearbox replacement may be the economic option open to the company. Now you could run into the availability or supply problems. As most gearbox suppliers are only likely to stock a few standard sizes & ratios of gearboxes on the shelf?

Getting a replacement gearbox for your project may take some time, as it could come from an international supplier. All this takes time, and many production lines will not allow machinery to be stopped for long. That is where a good engineering crew is worth their weight in gold to the company!

It is just sensible practice to carry minimum amounts of spares in stock or decide with suppliers to carry certain items in stock for you on a call-off basis. The machine manufacturers will also recommend a set of spares to carry for each machine. This is where good judgment and experience of the engineering crews with their knowledge of the production line, for the number of spares to carry.

This will pay dividends to the up time of the production line. The end results over time will show if you got it right or not, as history will show everybody the facts…? Few will know if you got it right! But the devil and all hell will know very quickly if you get it wrong…

In some circumstances, the whole machine replacement could become the best option open to you or the company. This is now often the case when working on modern high-speed, high-volume production line machinery.

So, with the loss of one key item, circumstances could escalate into a complete machine replacement… or a sizeable proportion of your production line being replaced or modernised.

If you are finding it difficult to source a part or gear that is made from plastic, you now have one more great option open to you. 3D printing. Where many small parts can be manufactured, in minimum time, be it gears or components on a fast turnaround basis.

3D Printing and the Gear Formula

These are now very economically manufactured plastic gears in a local environment in a production line fashion. Without all the hardware normally associated with a metal gear cutting shop. But having said that, you now find that the established gear cutting engineering workshops are now converting a room or office space to do this type of 3D printing manufacturing of various plastic gears and parts.

The recent Covid-19 pandemic of 2020 and 2021, seen a great boost in investment into this type of manufacture. As small entrepreneurs started up overnight to make many parts by 3D printing of components, for the medical industries. When larger companies were not able to fulfil new orders quickly enough to meet the demand in time to fulfil the sudden increase for modern design & manufacture of parts fast.

EDM workshops use the Gear Formula

EDM workshops equipped with the new range of EDM machines are now very advanced in the manufacture of special gears and other intricate components. These machines can be very efficient and accurate, (to within less than 20 microns), in producing one-off gears where and when the need arises.

Let’s not forget that at the other end of the scale of gear cutting we have very heavy industry, or should I say, large scale & heavy machinery, where many large gears are cut every day to fill this demand for specialist machinery. This type of machinery is not in every industrial site, or even in many countries.

But where they are, you may find many in a country or an area of need, such as mining, steel making, paper making, and of course heavy machinery manufacture to name just a few.

As a young apprentice or graduate engineer, it may be hard to visualise how gears are made or cut on average size gear cutters. Especially if you have not been working in this environment! Modern gear cutting machines are themselves, some of the most robust CNC machines available.

CNC Gear Cutting

Where they cut gear teeth to exceptionally fine tolerance and accuracy. This is regardless of the size or number of teeth being cut. Some gears are made in segments and the teeth are cut on each segment. the complete gear may only come together on the finished machine. The finished accuracy of each cut segment is so good, that you might think that it was cut as a one-piece gear, on the gear cutter!

Have a look at the following video which will give you an idea of how small or large gears are made & cut on a modern super-fast and accurate, CNC gear maker & cutting machines. Notice how the large gear steel blank is forged into shape, and the heat treatment is carried out later. I give every credit to these people and the companies that offer us all an insight, into some of these great workshops, tools, and methods that they use every day.

.