How does a Single Facer really work?

Perhaps if you are new to this industry and not familiar with how a Single Facer really works…! Well, I’ve got you covered, look at this informative video. Although it is only short, it’s amazing how well laid out and self-explanatory this video is. Their use of colour with the rotating items are particularly good, it’s amazing.

And don’t forget to give them a thumbs up! Once again thanks, guys…

Credit for this Video to Corrugator Tips.

This is only a brief introduction to the operating process of flute rollers forming corrugated paper. These rollers are usually enclosed in sound-prove panels and are in a hot steamy environment when they are running. So it is not easy to actually see the flute tips doing their work in the production line.

Best 5 Single Facer’s for Corrugators

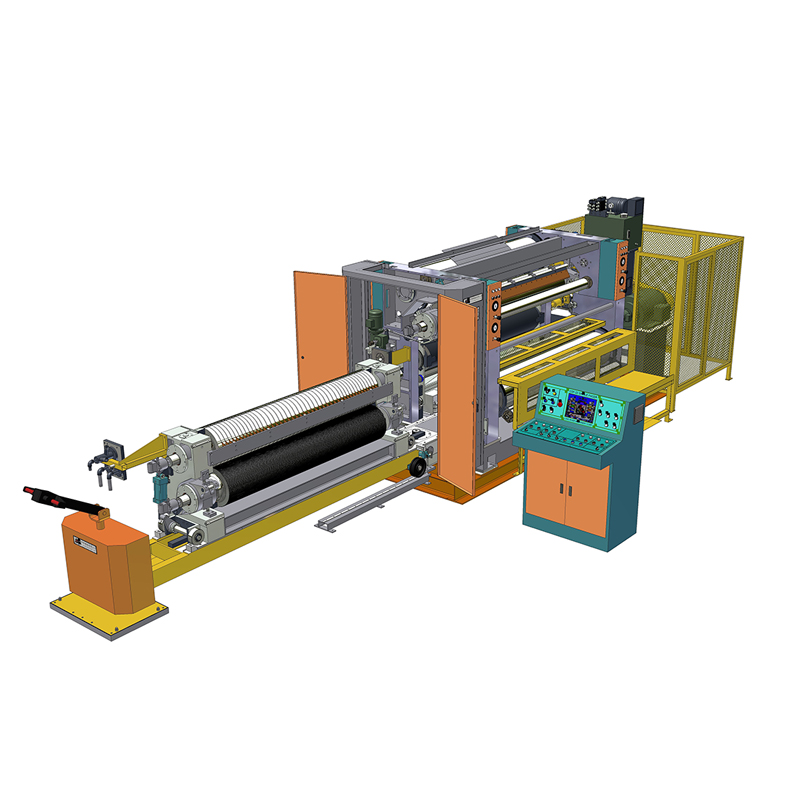

In this range of Long River machinery, we can offer many Single Facer models available for diverse types of applications. We can supply a variety of individual machine sizes to suit your existing corrugator or supply you with a complete corrugator Production Line.

Some of our customers have their own requirements to fulfill over the short or long term. This way they manage their corrugator improvements in a cost-efficient way that best suits their own expectations. New customers do not always really know what is available on the market today, in these cases, we will advise on best practices and the most up-to-date machinery that will meet their needs.

Tips for setting the speed difference between liner & Flute Rollers

Credit for this Video to Corrugator Tips.

Single Facer Machines are at the Heart of Corrugators.

Larger-size companies will sit down and decide on their overall requirements to cover their short-term, & long-term goals as a company. On the other hand, smaller companies may only plan to upgrade one or two machines at a time, as this meets their production requirements. In all cases, we will advise that customers should keep an eye on the future progress of the company’s expansion and allow for placing new machines in an optimum position. This way it will help them to avoid having to reposition existing or new machines unnecessarily in the future.

Great Quality Range of Single Facer

We can supply a variety of Single Facer machines, which will meet many of our customer’s requirements. Following is a list of the distinct types and sizes of Single Facer machines available. In this range, there are several machines for different speed ranges and cassette models that cater to many flute sizes. With these machines, cassette flute changes are carried out over a 7 to 15-minute time window.

These Single Facer machines run at higher speeds to help meet the high speed & high-volume production-oriented customers.

SF-120

Single Facer 120

Description

- This machine is exclusively for the formation of fluting paper and laminating a single facer.

- Maximum machine speed 130 m/min.

- This type of single facer is a particularly excellent choice for a corrugator speed of under 120 m/min and is suitable for changing the flute sizes frequently.

- Main drive using AC-25~30HP motor.

Features

- Fluting type: E-B-C-A-F-G flute (also can make any type of flute and cut-off size for the machine that the customer requires.)

- Upper and lower corrugated roller, pressure roller, and pre-heater roller are through by air cylinder.

- Set up Steam pipe system.

- Oil-immersed type gearbox driven directs the lower fluting roller, pressure roller, glue roller, and doctor roller.

- Single drive mechanism to avoid glue sticking to roll surface when stopping.

- The motion of the upper corrugated roller, pressure roller, and glue roller is operated by the hydraulic cylinder.

- Set up a hydraulic unit control.

- Fingerless design.

- Equipped with a suction stand, and lid which ensures that the corrugation of the fluting paper does not disperse in the process from the formation to the lamination.

Product Specifications

SF-80

Single Facer 80

Description

- This machine is exclusively for the formation of fluting paper and laminating a single facer.

- Max speed 80 m / minute.

- Fingerless/ Finger design.

- When using a fingerless design, a lower corrugated roller with a suction stand, and suction lid which ensures that the corrugation of the fluting paper does not disperse in the process from the formation to the lamination.

- Easy to maintain and operate.

- Special specifications offered contact with us.

Features

- As for the fluting type which can be used with the E-B-C-A-F-G flute sizes, we also can make any type of flute roller to the width of the customer machines as required.

- The Upper and lower corrugated roller, pressure roller, and pre-heater roller are operated by an air cylinder.

- Complete Setup of Steam-pipe system.

- Oil-immersed type gearbox driven direct to the lower fluting roller, pressure roller, glue roller, and doctor roller driven synchronously.

- Single drive mechanism to avoid glue sticking to roll surface when stopping.

- The motion of the upper corrugated roller, pressure roller, and glue roller is operated by a hydraulic cylinder.

- Supply and set up of a complete hydraulic control unit.

Product Specifications

SF-90

Single Facer 90

Description

- This machine is exclusively for the formation of fluting paper and laminating a single facer.

- Maximum machine speed 100 m/min.

- This type of single facer is an excellent choice for a corrugator machine speed under 100 m/min and is suitable for changing flute sizes frequently.

Features

- There is a special purpose for the pneumatic system.

- It can be increasing upper roller and pressure roller buffer adaptation to get excellent laminating to kraft paper and fluting paper.

- The backing of the glue unit also adopted the same pneumatic system. Lower corrugated roller by suction fluting profile with the pasted device.

- The upper and lower corrugated roller, pressure roller, and pre-heater by steam to heating with steam valves and trap system.

- The main drive uses an AC-15~25HP motor and it under high-speed running can hold the web out stable.

- The corrugated roller can be lifted out and changed to a different fluting-size roller in less than 30 minutes.

Product Specifications

SF-150

Single Facer 150

Description

- This machine is exclusively for the formation of fluting paper and laminating a single facer.

- The maximum speed of this machine is 160 m/min.

- The production speed of 150m/min. With 30~75 HP Motor and the speed can be adjusted.

Features

- As for the fluting type which can be utilised with C-A-B-E flute sizes.

- We also can make any type of flute rollers that suit the width of the machine that suits the customer’s requirements.

- The Upper and lower corrugated roller, pressure roller, and pre-heater roller are operated with an air cylinder.

- Set up has a full steam recovery system.

- Oil-immersed type gearbox driven with a Universal Joint, directing to the lower fluting roller, pressure roller, glue roller, and doctor roller.

- Single direction mechanism, to avoid the glue sticking to the roller surface when stopping.

- The motion of the upper corrugated roller, pressure roller, and glue roller is operated by a hydraulic cylinder.

- The machine has a full setup of a complete hydraulic control system.

- Fingerless design.

- Equipped with a suction stand, matching up with a suction lid, which ensures that the corrugation of the fluting paper does not disperse in the process from the formation to the lamination.

Product Specifications

Cassette Fast Change Single Facer

CSF-22-(4 to 8)

Cassette Type Single Facer 22

Description

- This machine is exclusively for the formation of fluting paper and laminating a single facer.

- The max speed of this machine is 200m/min.

- The production speed also can reach 180 m/min. with a 30~50HP Motor, and the speed can be adjusted.

Features

- As for the fluting type which can relate to the E-B-C-A-F-G flute, we also can make any type of the flute roller and size for the machine that the customer requires.

- Upper and lower corrugated roller, pressure roller, and pre-heater roller are through by air cylinder.

- Set up steam recovery system.

- Oil-immersed type gearbox driven directs the lower fluting roller, pressure roller, glue roller, and doctor roller performed by steam.

- Single drive mechanism to avoid glue sticking to roll surface when stopping.

- The motion of the upper corrugated roller, pressure roller, and glue roller is operated by the hydraulic cylinder.

- The Setup is run with a hydraulic control system unit.

- Designed with a fingerless and vacuum blower by positive pressure to keep fluting profile when glued.

- This single facer uses a cassette quick-change flute profile and can change a cassette within 20 minutes.

- The steam joints and drive clutch also adopt a quick-change device to save time in changing flute sizes.

Product Specifications

Specification

The Roller diameter ø 360:

| CSF-22-4 | CSF-22-5 | CSF-22-6 | CSF-22-7 | |

| Width of paper | 1600 | 1800 | 2000 | 2200 |

| The highest speed | 220 m/min | |||

The Roller diameter ø 408:

| CSF-22-6 | CSF-22-7 | CSF-22-8 | |

| Width of paper | 2000 | 2200 | 2500 |

| The highest speed | 250 m/min | ||

SF-200H

Single Facer 200 Cassette Model

Description

- This machine is exclusively for the formation of fluting paper and laminating a single facer.

- The normal production speed is 180 m/min. with 30~50HP Motor and the speed is adjustable.

- The maximum speed of this machine can be 200 m/min.

Features

- As for the fluting type which can be used, E-B-C-A-F-G flute, we also can make any type of flute & width of roller size for the customer’s machine as required.

- The Upper and lower corrugated roller, pressure roller, and pre-heater roller are operated by an air cylinder.

- Set up steam recovery system.

- Oil-immersed type gearbox is driven directly to the lower fluting roller, pressure roller, glue roller, and doctor roller performed by steam.

- A single drive mechanism is used to avoid glue sticking to the roller surface when stopping.

- The motion of the upper corrugated roller, pressure roller, and glue roller is operated by hydraulic cylinders.

- This setup uses a hydraulic control system.

- Fingerless design, equipped with a suction stand, matched up the suction lid, which ensures that the corrugation of the fluting paper does not disperse in the process from the formation to the lamination.

- This single facer uses a cassette quick-change flute rollers within 10 to 15 minutes.

- The steam joints and clutch drive also adopt a quick-change device, to save more time in changing the flute roller cassette.

Product Specifications

Specification

| Model No. | SF-200-3 | SF-200-4 | SF-200-5 | SF-200-6 | SF-200-7 |

| Width of paper | 1400 | 1600 | 1800 | 2000 | 2200 |

Corrugated Boxes

Industrial engineers

Surface Roughness of Rollers

Corrugator Chop Knife

.