We are going to step back into history for a few moments and look at the need to develop a constant and widespread power supply to fulfil the needs of expanding countries.

Their main power force lay behind how efficient their army was, in their use of weapons on the field of battle and how quickly they could be replaced, reinforced, or even to rebuild their army…?

To achieve this, what better way than to build up your army fast!

But how can you build up an army fast, once you got the men…

You now need to train & equip them with materials and tools of war?

In the olden days, slave labour was a very important resource to have to hand, and they could be diverted very quickly from one task to another, to make or do whatever was required on the day…!

Now move forward to the mid-1600s and things were heating up in Europe and elsewhere.

Forced labour was not sufficient to build or make up a war chest any longer.

You now needed a more skilled workforce behind you, to build up the kit for an army or navy…!

O yes, and a vast supply of raw materials required to make up your new kit for war was very important…!

Technology was Changing…!

The rise of scientific technology was the new kid on the block, but not many were up to speed on how to implement all the aspects of this new rising force.

One of the first great providers to spread this new knowledge was the hand-operated printing press.

Note, the extensive use of wood in this machine.

Now, many books could be printed and major works covering various aspects of information.

Could be bought and students would now be able to study in colleges & from homes across Europe and elsewhere.

The Rise of Steam Powered Engines

Jeronimo de Ayanz y Beaumont invented a steam-powered water pump and was granted a patent by the Spanish monarchy in 1606.

Around the mid-1650s the Spanish had been using steam power to drain water from their silver mines…?

No designs have survived to show how these steam-driven pumps were made…?

Could Thomas Savery or his friends have visited Spain during this time…?

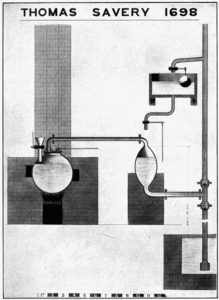

Then about 50 years later or so, Thomas Savery from Devon invented and patented a device in July 1699. It had 2 chambers, that were used to create a vacuum with steam to draw in water, then push it up a pipe to exit!

This steam-fired engine had no moving parts…!

It could draw water from a depth of 25 feet.

Some of these devices were created to pump water from wells and mines in Devon & Cornwall, areas of South-West England.

Later he called it “The Miner’s Friend” his original patent was for 14 years, then a new Act of Parliament gives him another 21 years of protection, called “The Fire Engine Act”.

He met with Thomas Newcomen in Dartmouth, who was an ironmonger. This is a person who sells iron and makes various items out of iron for sale.

It is thought that Savery may have bought, or had Newcomen make various items out of iron for Savery’s steam engines.

Newcomen had his own ideas to harness the power of steam much better than Savery’s devices or Engines could do.

But he could not make steam engines as Savery’s patent-protected this invention.

Thomas Newcomen could not wait until the patented time would run out…! So the 2 men come to an agreement.

Newcomen was also interested in building a better pump to drain the Cornish mines so with the help of John Calley they achieved a better pump than Savery’s pump.

In 1712 Newcomen patented a new type of engine, the Atmospheric Engine. That could pump water from any depth, with the use of rods attached to the water pump.

While the steam engine was housed in a building at the top of the mine shaft.

The water pump was placed straight down into the mines base point. And the pumped water piped to the surface and run-off.

Through Thomas Savery, Newcomen knew of the high costs involved for keeping teams of horses that were used to turn jines, they were one of the devices used in those days to pump out mines.

Just to give you an idea of the scale of operations in a larger mine in those days, they could have up to 500 horses available for pumping water alone.

The first operational Newcomen engine was built in 1712 for Coneygree Coal Works In Staffordshire.

This pump was 21 inches in diameter by 7 feet 10 inches long. The engine made 12 strokes a minute.

Each stroke lifted 10 gallons of water up 153 feet, or equal to 120 gallons a minute.

By the early 1730’s there were over 100 steam-heated Atmospheric Engine’s at work throughout the UK and abroad.

How to Buy a New Steam Engine

To help companies buy and pay for these engines, Thomas Newcomen worked out a method or formula on a percentage basis of the cost savings, against the costs to run teams of horses for the same amount of work done.

Soon he was in high demand to make and build larger engines all over the country.

One of these rugged and very reliable engines that worked 24 hours a day, was still operating 127 years after it was first installed at Pentich.

It would take about 50 years to create the environment for this new wave of information of Steam Engineering technology to develop, and the huge expansion in manufacturing industries was the result of these actions that were to follow.

Bit by bit each problem would be solved and the knowledge acquired was becoming more and more widespread.

By the mid-1700’s most of the individual elements were well known about, but were only capable of being implemented by a few Entrepreneurs of the day!

James Watt:

James Watt was employed as an instrument mechanic at Glasgow University, and while repairing a model of an old Newcomen Atmospheric Engine in 1765.

When he observed and experimented with this Engine, he discovered that he could make these engines very efficient by modifying the way the hot steam was cooled, without cooling down the hot piston and Steam Cylinder!

In 1769 Watt patented a separate steam condenser that made the Newcomen Atmospheric Engine much more efficient in use.

His new condenser when fitted to the old Newcomen engine, would allow the same engine to run on 1/3 of the fuel previously used for the same amount of work?

James Watt would refine Newcomen’s formula for costs savings, but now it was the cost of coal savings he would apply!

Watt went on to measure and define the work a Draft Horse could do?

He found that a large horse could pull a load of 150 lbs when walking at a speed of 2.5 miles per hour.

His work would result in the following formula of power; 1 Horsepower = 33,000 foot-pounds of work.

He used the term “Horsepower” which is still in use today, to show the power rating of an engine or motor.

Now, he could calculate and make the size of a new engine, to match the power of any job it was required to do!

But few could implement the new system completely. They required access to large amounts of finance to move this technology forward.

With private finance available to only a few developers for the new Steam Powered Engine.

It meant that this newfound knowledge was slow to be created for widespread use.

However, many small enterprising individuals would attempt to improve on what they had heard about, or seen for themselves.

And through their efforts, many new developments would be created to propel the rise of the Steam Engine. More of which, began to be used to power the new expanding industries.

The development of the new banking system around the 1790’s would come to the help of many companies, by introducing new ways to get finance for their new projects.

During the Napoleonic wars, approx from 1791 to 1817 would see a huge expansion in new and old industries across Great Britten. With the help of the improved methods of factory manufacturing knowledge. Goods became cheaper to buy and were in demand around the world.

This would help to expand their businesses and would create brand new businesses over the next few centuries.

By the early-to-mid 1800’s these new manufacturing businesses would be centred around the building of multi-storey factory premises, powered by one huge steam engine.

With a very noticeable new feature on the landscape, a tall chimney.

That naturally drafted the fire of the boilers that created the steam generated to drive the steam engines in every new Mill or factory building.

Enter the first industrial revolution…!

Arkwright’s factory system, coupled with Watt’s new improved designs for the low-pressure steam engine of Newcomen’s, by then, a 60-year-old design?

James Watt would at first improve Newcomen’s atmospheric engines, where (steam created a vacuum) and fit upgrades to the old engines, which give them a new lease of life.

These parts were mostly made at the new Boulton & Watt Soho factory in Birmingham.

How this partnership came about, is also a very interesting subject of events, that were to propel James Watt’s career beyond his wildest dreams.

Beam Engines

It is said that by 1780 there were about 2000 Newcomen engines running in various industries across Britain & Europe primarily used for pumping water.

These engines were also known as Beam Engines.

Often the engine and boiler were in a brick building, while the pump was down the mine attached to the outer end of the BEAM, outside the building.

Matthew Boulton would later, urge James Watt to turn his attention to making a Rotary Steam Engine.

There were many existing businesses that were running with water wheels for power to turn their machinery. But these would have their own drawbacks, such as flooding and dry spells, and not let us forget frost and ice in colder parts of the country.

Rotary Engines

Boulton realised that a rotary steam engine could easily take over from the water wheel to drive the present mill machinery, in many of the water-powered enterprises of the day.

If this could be achieved, we would have the World as our marketplace…!

Later, James Watt would create a new more compact and efficient design with higher-steam pressure, (5 to 10 psi) with the engines running in rotary motion by the use of gears, the Sun and Planet.

To achieve even greater efficiencies, came from one of Boulton & Watt’s sub-contractors.

John Wilkinson was using a water wheel to power his machinery when the demand for boring out mostly cast iron and bronze objects was beyond the capacity that he could handle.

Wilkinson was selected by Boulton & Watt to bore out their cast Iron Steam Engine Cylinders because he could finish the bore surface so smooth and accurate, they were the best around at the time.

At first, this was done by turning the item to be bored by a water wheel, with sandstones roped to a pole mounted on a trolley that moved on 2 flat iron tracks.

The trolley was moved in-&-out of the bore by hand, to grind the full length of the bore.

It took ages, days, or weeks to do each job…!

You could say he had one of the first Quality Control systems in place, whereby objects had to meet a given required finish and size before they would be dispatched by him.

These very qualities were to stand him in good stead because he now would get large numbers of cannons to make for the army and navy of the day.

To meet this demand, he set about how he could shorten the time taken to achieve the finished bore.

He goes on to invent the world’s first Metal Boring Machine, in 1774, crude they may have been at first, but soon they were precision machines tools.

As he pioneered boring out cast-iron goods, like cylinder bores for Watt’s steam engines and cannon bores for the army & navy use. These were made at and around his Bresham Ironworks near Wrexham.

Wilkinson was soon able to bore out cylinders, which was made so accurate, in finishing the bore surface and size over the length of the long steam cylinders. That Boulton & Watt used no other company to do this work for them.

For those who would like to see one of these first steam-driven pumps, you can view the Smethwick Engine at work on open days at Birmingham Museum, in the Think Tank. I have seen this engine in action many times, especially on the bicentenary of James Watt’s death in August 2019.

There was no stopping the new forces that were to follow…

In 1781 Watt was to produce a new rotary motion steam engine, using what became known as the Sun-and-Planet gear.

He devised this method to obtain rotating motion, as others had a patent on the simple crankshaft.

One early example of this type of engine still exists “The Lap Engine” built-in 1788.

It ran unaltered for 73 years, driving 43 polishing machines at Boulton & Watts Soho factory.

This engine was double-acting and used Watts famous parallel motion to keep the piston rod moving in a straight line.

As rotary power would now be available to run in winter and summer, day and night.

Many new and old industries would benefit from this new steam engine system.

Weather and climate conditions would no longer hold back production in any industry.

The Napoleonic wars from the early 1790’s, were to give all UK industry a boost.

As the demand for equipment to supply the Army and Navy with a new range of battle equipment on land and sea would reach new heights of production volumes.

Britain was now at the forefront of this new industrialisation and the countries would prosper for many years to follow.

Coal mining, iron making & later steel making, transport by ships and trains, were the big ones to forge ahead, with the use of his new Rotary Steam Engine.

Closely followed by textiles, paper making & a completely new range of industries to supply and support the larger manufacturing industries, all were using the new Rotary Steam Engine designs.

These were now reaching new levels of production to satisfy the growing demand for more & more products to be manufactured of every possible item, from pins to ships.

Demand could not be satisfied

The global demand could not be satisfied, as so many other countries were to build up their own industrial economies, and in time these would present a challenge to the home market and the growing world trade.

The rise of Steam power would grow rapidly from about the mid-1780’s onward for the next 120 years or so.

By the 1830’s steam power had outstripped all other types of power sources that were in use.

This was the start of a major decline of water wheels and windmills across the nation, as all modern industries required a more regular power source!

The Decline of Animal Power

The use of animal power in the manufacturing industries, by 1840’s was now long gone.

But; canal, road transport, farming and the Armies, of many nations, were still in full swing with large numbers of horses employed in everyday use.

Over the course of the next 80 years, or so. The use of horses in these industries would also see a large decline as the introduction of other forms of road transport would become economically available.

Canal transport would see the widespread use of small onboard steam engines and later the use of petrol and diesel engines. So large numbers of horses would no longer be needed here either.

Soon to follow would be the decline of the canal system itself as a major carrier of goods around the country.

As trains became more efficient and the main carriers of major quantities of goods to and from the ports and factories.

Also, the use of steam trains in the transport of people to and from work in large numbers was to become an industry in itself.

Almost 300 Years Later

Steam is still in use in many industries today, almost 300 hundred years later.

In my industry, corrugators use modest quantities of steam to make the corrugated board needed for boxes.

But with a huge change in the control and type of fuels used to raise steam to the higher pressures required across many industries today.

Gone are the tall chimney stacks, that once dominated the skyline of many towns & cities, and the numbers of men that were needed to run these boilers in the old days.

Today, the modern boiler may not even be in a “Boiler House” but placed in an area on the factory floor, just like any other piece of machinery.

Many would not even realise that it is a steam boiler at all…?

They are now much smaller & cleaner in operation and run fully automatically.

They are almost silent, with no steam leaks and above all no loss of heat into the surrounding area.

These are very efficient pieces of machinery and good care is taken, to keep them that way.

.