My Services

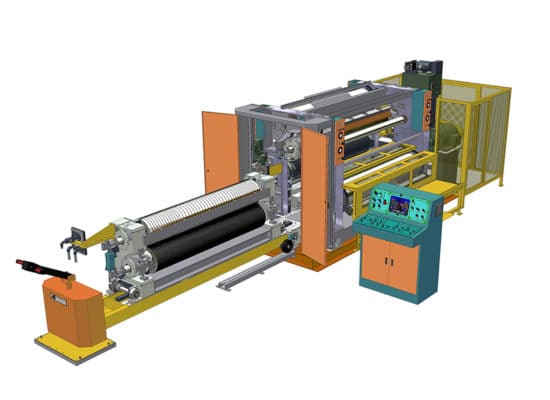

Corrugator Cutter Machinery

This No1 marvel of Corrugator Cutter machinery design in using modern engineering & innovation techniques is helping to make this corrugator NC Cutter a top notch machine

Automation

The experience of our engineering partners in Industrial Automation over many years producing systems & special purpose machines is based upon a sound understanding of our best automation techniques and knowing the benefits that are possible…!

Auto Starch Glue Mixing System

This information was updated in January 2022, as the Covid-19 Lockdown Crisis takes its toll on many companies…! This system is still one of the best around. This Auto Starch Glue Mixing machine will suit a wide variety of modern and older types of corrugators as a Fully Auto Starch Glue Mixing System. It will […]

Corrugator Consulting

In this field of modern project specialists of Corrugator Consulting, very much sought-after engineering expertise. We work with a well-established UK Corrugator Consulting Company, with many years of unique experience in this area of activity. Who can demonstrate their Corrugator Project Consulting ability & inspire a keen understanding of their expertise? Between us, we can […]

Latest Blog News

Corrugator Conveyor Systems

Single-face corrugated cardboard products are by their very nature extremely difficult products to handle on most corrugator conveyor systems. This is a very flimsy product to keep under control at the best of times… So, keeping control of it at all stages is paramount for you to efficiently run single-face products at higher speeds. Single […]

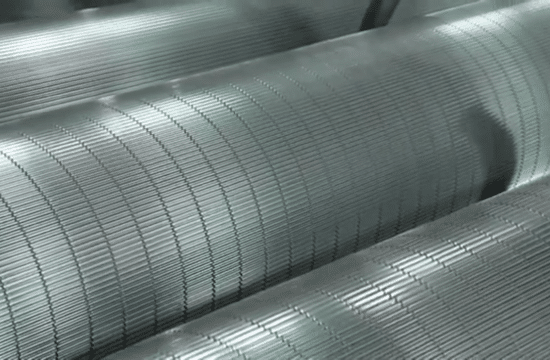

Flute Rollers For Single Facer Corrugators

Maintaining Flute Rollers in Single Facer Make sure that these particularly important corrugator flute rollers in a Single Facer, are looked after in the best possible manner. Many operators become familiar with this process after working on the corrugator for some time. These flute rollers are a crucial part of any single facer, and the […]

Best 5 Single Facer for Corrugators

How does a Single Facer really work? Perhaps if you are new to this industry and not familiar with how a Single Facer really works…! Well, I’ve got you covered, look at this informative video. Although it is only short, it’s amazing how well laid out and self-explanatory this video is. Their use of colour […]